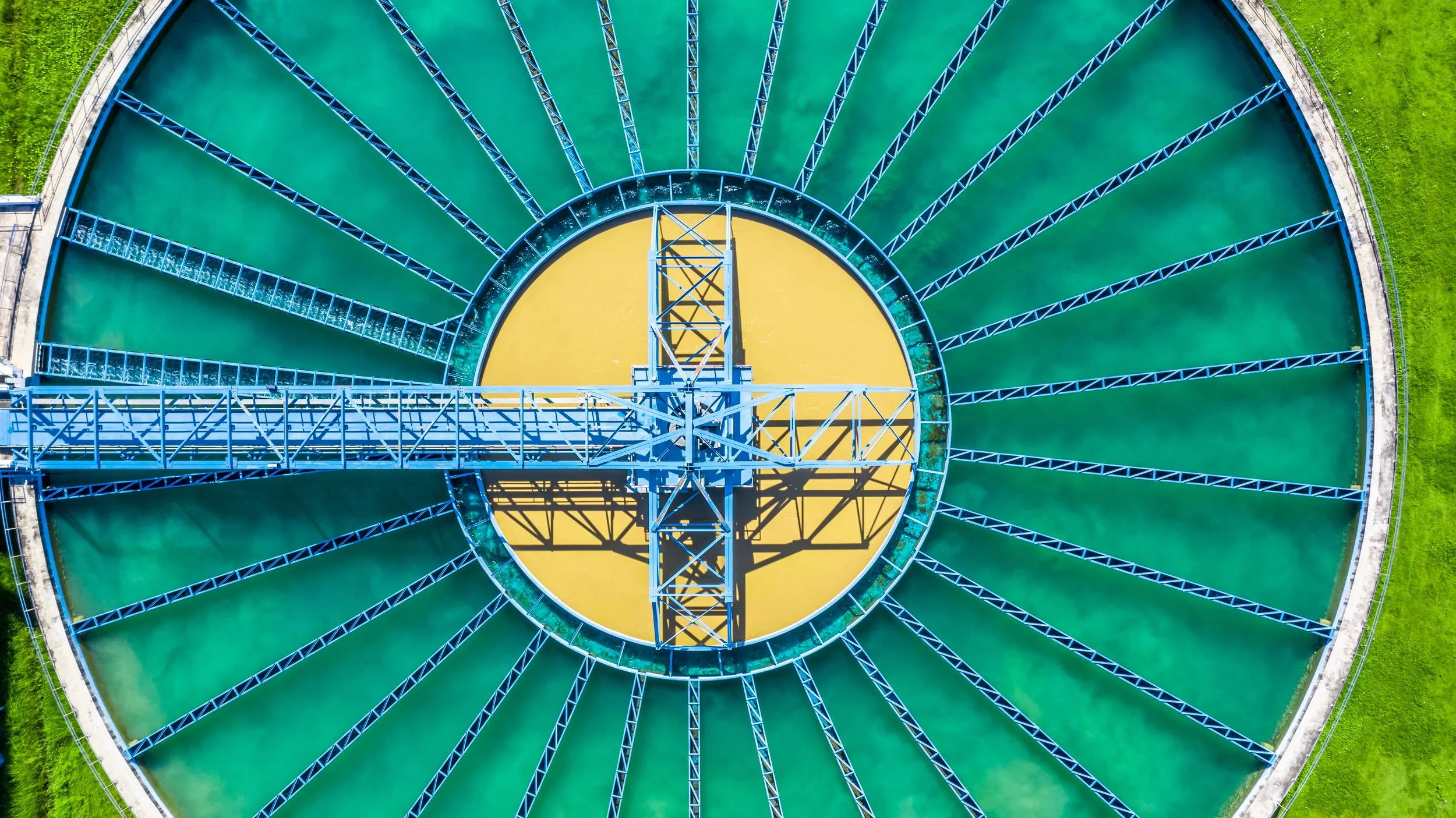

Waste water treatment.

→ INDUSTRIES / WASTE WATER TREATMENT

Stable wastewater treatment depends on controlled influent conditions, and XPEL evaporation provides upstream volume reduction from ponds to help protect biological, mechanical and chemical treatment processes from overload.

WASTE WATER TREATMENT

Waste water treatment systems often experience fluctuating influent volumes driven by industrial discharge, stormwater infiltration and production-related variability.

These shifts make it difficult to maintain predictable hydraulic loading, placing strain on clarifiers, aeration basins, filtration assets and chemical dosing systems.

When flows surge or concentrations spike, treatment units can be pushed beyond design limits. This increases the risk of solids washout, reduced biological activity, fouled membranes and non-compliant effluent. Facilities may need to rely on emergency bypasses, increased chemical dosing or rapid operational adjustments to remain functional.

XPEL evaporators help stabilize these conditions by reducing excess water stored in wastewater ponds before it is fed into downstream treatment stages. By evaporating surplus water from these ponds, XPEL creates hydraulic breathing room during peak periods, limits the volume entering treatment circuits and supports steadier plant performance under variable influent conditions.

XPEL water evaporation technology provides a practical, scalable way for wastewater plants to manage fluctuating conditions without expanding infrastructure. This upstream volume reduction strengthens treatment reliability, supports regulatory performance and helps facilities maintain consistent operation across changing influent profiles.

Waste water treatment applications.

■

Facilities handling wastewater must manage shifts in influent volume and composition created by industrial activity, storm events and seasonal patterns. These fluctuations can increase hydraulic pressure on treatment assets and reduce operational stability. XPEL integrates into these environments by reducing water in upstream ponds, helping treatment plants maintain more controlled, predictable operating conditions.

-

Wastewater from food processing contains high organic loads. XPEL reduces excess ponded water before it enters treatment, helping plants maintain steadier biological and mechanical performance.

-

Produced water and industrial effluent place heavy demand on treatment systems. XPEL lowers peak volumes stored in feed ponds, reducing the hydraulic shock entering separation and treatment units.

-

Mining generates contaminated runoff and process water that requires specialized treatment. XPEL evaporates surplus water in ponds, creating hydraulic space that supports consistent treatment outcomes.

-

Municipal systems manage mixed domestic and industrial flows that surge during wet-weather events. XPEL reduces pond levels upstream to help facilities keep treatment processes within safe hydraulic limits.

-

Older industrial sites are home to long-standing contamination in ageing ponds. XPEL evaporates stored water to relieve hydraulic pressure and improve the reliability of remediation treatment systems.

-

Pulp and paper wastewater is rich in organics and chemicals. XPEL lowers the volume in surge or equalization ponds, supporting stable operation of primary and secondary treatment assets.

-

Manufacturing wastewater often varies in strength and solids content. XPEL reduces influent volume at the pond stage, helping treatment plants maintain compliance and efficiency across fluctuating conditions.

PRODUCTS

Land based

evaporators

Fully customisable and bespoke in design, our XPEL land based water evaporators are available in a range of sizes enabling operators to reduce the risks associated with excess water and ensure environmental compliance with a wide range of water processing capabilities.

Pontoon

evaporators

When land based units aren’t an option, the XPEL Pontoon Series evaporator is a water management solution that can be relied on to help reduce the risk of excess water and ensure environmental compliance by reducing the volume of water stored on-site using mechanically enhanced evaporation.