Evaporation efficiency modeling

→ ENGINEERING / EVAPORATION EFFICIENCY MODELING

Accurate system expectations through evaporation efficiency modeling at XPEL are driven by the Systems and Environmental Engineering Division, turning climate and water data into practical insight on how an evaporator will perform on site.

EVAPORATION EFFICIENCY MODELING

Evaporation efficiency modeling gives XPEL a clear view of expected field performance before a system reaches site. This early insight strengthens engineering decisions and ensures each configuration is built for the conditions it will face.

XPEL Systems and Environmental Engineering Division evaluates climate patterns, atmospheric behavior and water characteristics to understand how these factors interact during mechanical evaporation. Temperature, humidity, wind speed and seasonal shifts are analyzed alongside solids loading and water chemistry to produce a realistic efficiency profile for each location.

This modeling informs critical design decisions, including capacity selection, nozzle configuration, duty-cycle planning and placement strategy. By understanding how an evaporator will perform during peak heat, high humidity periods or rapid environmental changes, engineering teams configure systems that maintain stable output across a full operating year.

Efficiency modeling also identifies potential constraints before commissioning. This includes recognizing conditions that could limit output, anticipating seasonal bottlenecks and determining when additional evaporation capacity may be required. The result is a more predictable, well-planned water-management strategy aligned with industrial pressures and environmental obligations.

Precise evaporator efficiency

XPEL evaporation efficiency modeling incorporates detailed atmospheric and site-specific data to guide more precise engineering outcomes. Inputs such as humidity, rainfall, elevation, pan evaporation, Total Dissolved Solids (TDS), and temperature are combined to understand the evaporation profile achievable over a full 12-month period in any given climate.

These insights shape engineering decisions around capacity requirements, mechanical configuration and alignment with local environmental behavior. By understanding how these variables interact across different seasons, XPEL designs evaporation systems that maintain dependable output in both stable and highly variable conditions.

This data-driven approach positions each configuration to meet the long-term demands of complex industrial environments. The result is an engineered solution calibrated to real climate behavior, predictable performance windows and the specific operational pressures present at the site.

PRODUCTS

Land based

evaporators

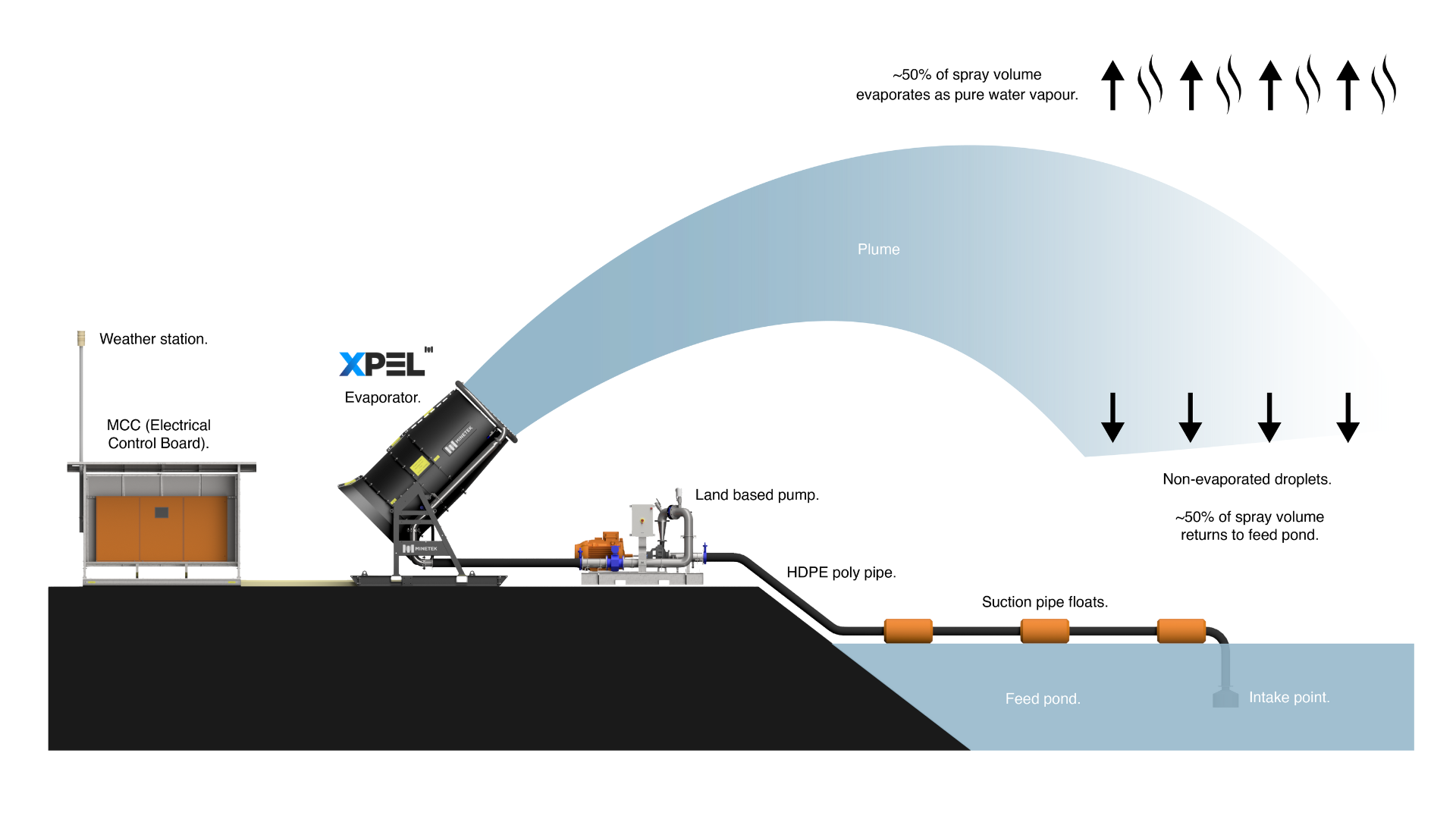

Fully customisable and bespoke in design, our XPEL land based water evaporators are available in a range of sizes enabling operators to reduce the risks associated with excess water and ensure environmental compliance with a wide range of water processing capabilities.

Pontoon

evaporators

When land based units aren’t an option, the XPEL Pontoon Series evaporator is a water management solution that can be relied on to help reduce the risk of excess water and ensure environmental compliance by reducing the volume of water stored on-site using mechanically enhanced evaporation.