→ ENGINEERING / ENIVIRONMENTAL MANAGEMENT SYSTEM (EMS)

Environmental Management System (EMS)

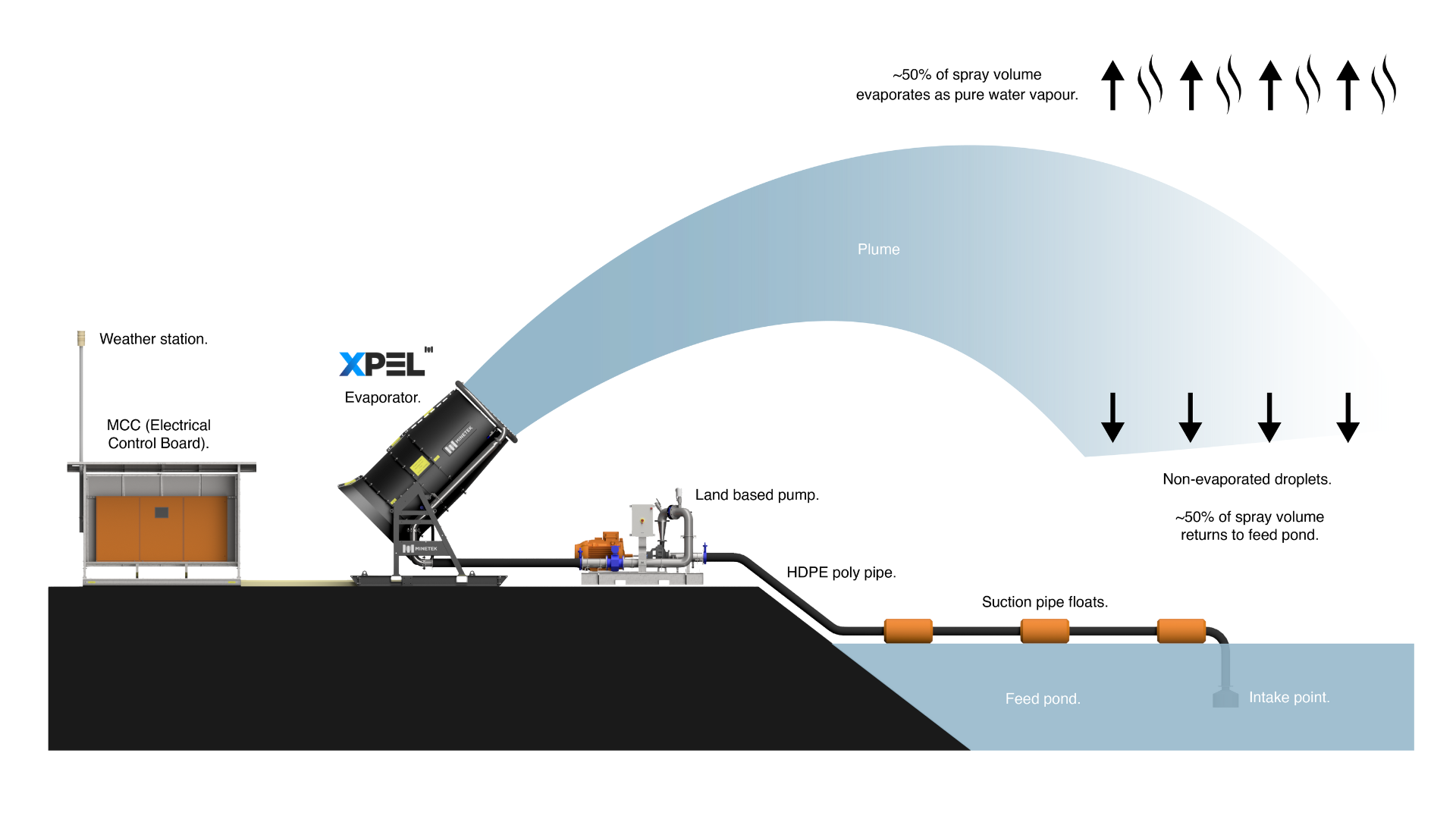

XPEL Environmental Management System (EMS) delivers real-time control over evaporation performance, adjusting system behavior to shifting weather, water conditions and regulatory limits.

ENVIRONMENTAL MANAGMENT SYSTEM (EMS)

XPEL Environmental Management System (EMS) keeps evaporation systems performing at their best by adjusting operations as conditions change throughout the day, adding a higher level of control that maximizes the capability of our high-throughput evaporators.

The EMS operates as an integrated control layer that stabilises evaporation performance under changing field conditions. It tracks real-time weather, water behavior and operational parameters to keep output predictable across shifting environmental pressures.

Wireless connectivity and remote PLC access provide authorized teams with live visibility of environmental data and system behavior across multiple locations. This continuous insight strengthens decision-making and maintains operational continuity during high-volume events or rapid onsite changes.

Inputs from weather stations, flow sensors and atmospheric monitors allow the EMS to automatically adjust operating parameters such as flow rate, pressure and duty cycle. These automated responses ensure the system aligns with humidity, temperature, rainfall and wind conditions without manual intervention.

By coordinating environmental data with operational settings, the EMS enhances efficiency, protects equipment limits and maintains compliance across industrial and municipal environments. This intelligent control framework delivers steady, resource-efficient evaporation in climates where conditions shift frequently and unpredictably.

Autonomous control

& enhanced efficiency

XPEL Environmental Management System introduces autonomous control features that manage routine evaporation workflows without the need for constant oversight. Start-up and shutdown sequences can be triggered automatically based on environmental thresholds or operating conditions, creating a consistent and efficient cycle that reduces idle time and unnecessary energy use.

The EMS continuously captures operational data, including runtime patterns, environmental shifts and output behavior across the evaporation system. This information builds a detailed performance history that engineering teams can review to identify trends, refine settings and strengthen long-term operational stability.

Designed to accommodate a wide range of site requirements, our EMS scales effortlessly from small installations to complex industrial water networks. Configuration flexibility ensures that the system adapts to changing operating parameters and increased evaporation demand without compromising reliability.

By combining automated control, live environmental awareness and comprehensive analytics, the EMS enhances the overall performance of XPEL mechanical-evaporation systems. This integrated capability streamlines water management processes and supports efficient, predictable operation in dynamic industrial environments.

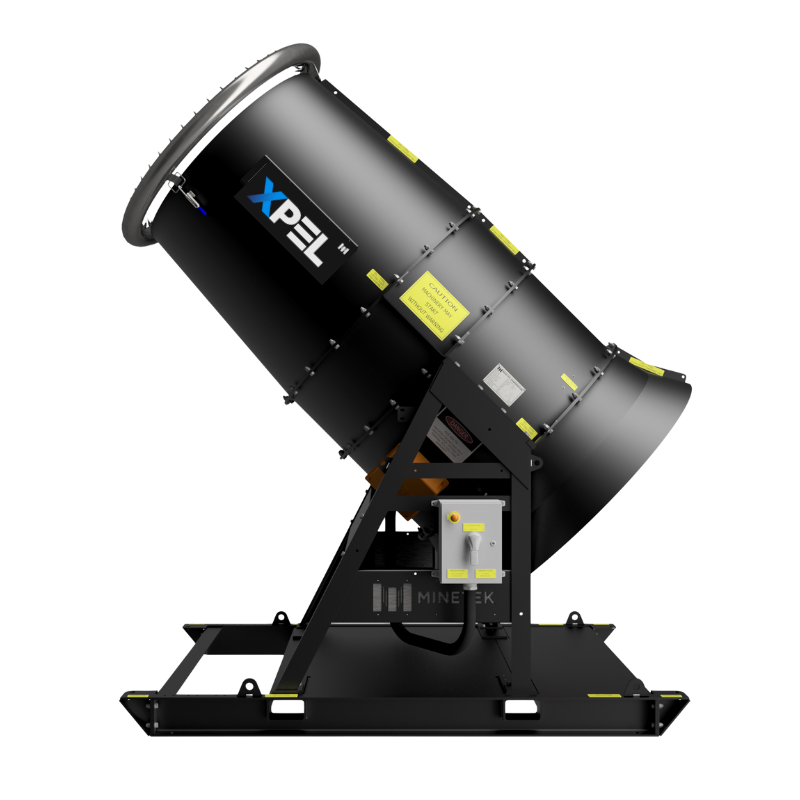

Low Fouling Nozzles

Engineered to process acidic, caustic, high-TDS and high-TSS water across the full pH range while maintaining consistent evaporation output.

Construction Materials

Built with site-matched material options designed to withstand harsh chemistries and demanding industrial environments.

Water Rail

Supplies high-volume wastewater to the nozzle array for controlled atomization and efficient evaporation performance.

Rapid Deployment

Integrated lift points and forklift pockets enable fast relocation across ponds, dams or site layouts.

Compact & efficient

A small footprint, low power demand and minimal moving parts drive strong operational efficiency and long-term cost control.

Water management industry applications.