Wastewater plants.

→ APPLICATIONS / WASTEWATER PLANTS

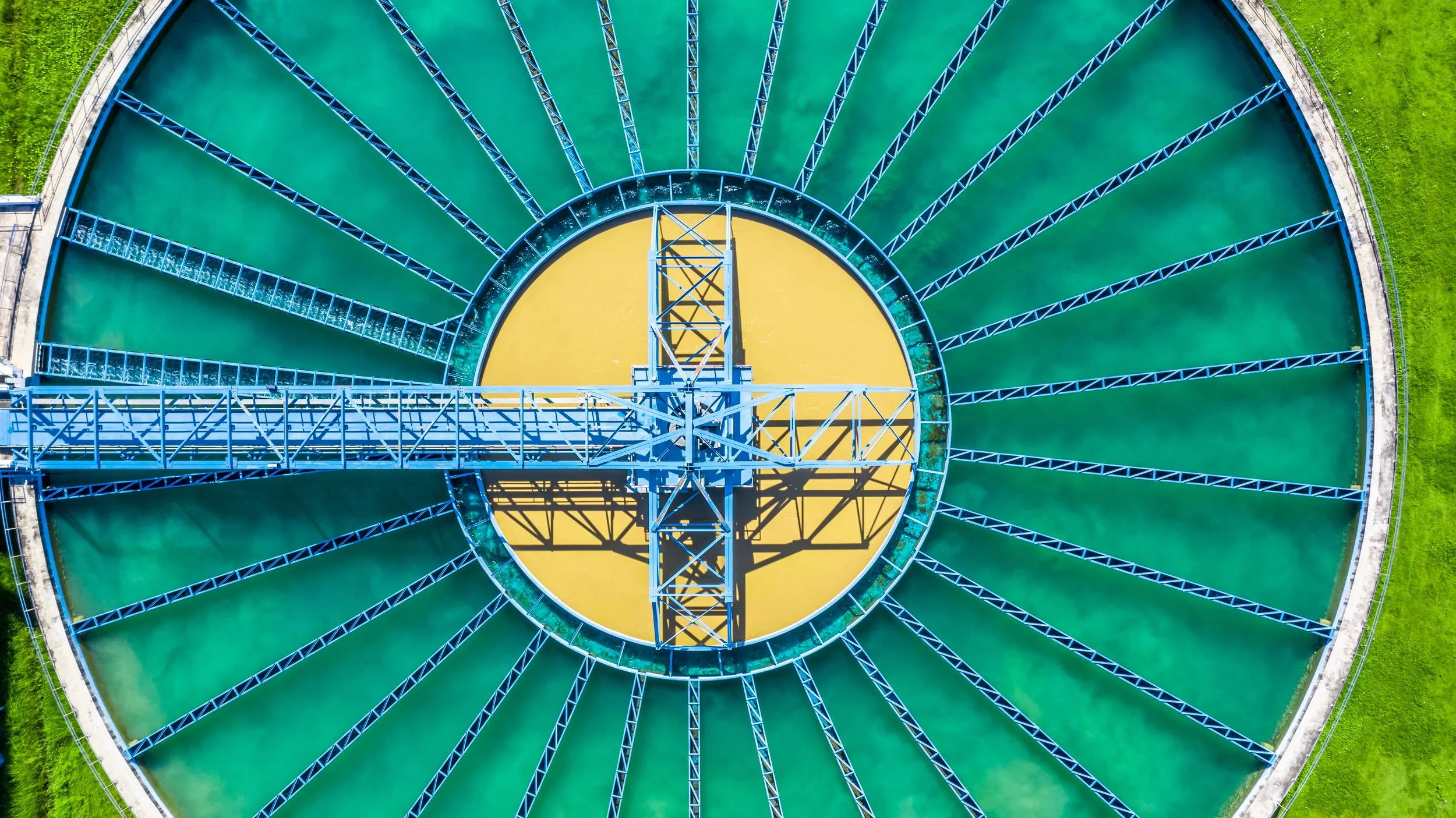

XPEL evaporation reduces excess water entering overloaded treatment circuits, easing demand on clarifiers, aeration systems and filtration assets so plants can maintain more stable, reliable performance.

WASTEWATER PLANTS

Wastewater plants regularly face fluctuating inflow volumes, high-strength industrial contributions and legacy infrastructure that operates close to its hydraulic limits.

As loads rise, clarifiers, aeration basins and filtration systems experience increased pressure, reducing operational stability and restricting treatment capacity.

Surplus or difficult-to-treat water does not disappear on its own. When inflows surge during storm events, industrial discharge cycles or seasonal peaks, treatment systems can become overwhelmed, raising the risk of bypass conditions or off-spec discharge.

XPEL fits into this environment by efficiently reducing excess water before it reaches these constrained assets. Our evaporators remove only the clean water fraction, allowing plants to bring inflow volumes back within manageable operating ranges without altering water chemistry or interfering with treatment processes.

By lowering hydraulic stress and smoothing daily flows, XPEL helps wastewater plants maintain steadier operation, protect core equipment and reduce their exposure to emergency responses such as hauling or temporary storage. Backed by decades of field-proven engineering, XPEL evaporation technology offers a scalable, cost-efficient solution for handling challenging water loads in complex treatment networks.

Wastewater plants operate under shifting conditions driven by industrial inputs, domestic load variability and weather-related surges. These shifts challenge hydraulic balance, equipment uptime and compliance requirements. XPEL strengthens plant resilience by reducing excess water volumes upstream, giving facilities more operating space, steadier flows and greater flexibility during high-demand periods.

Wastewater plants applications.

■

-

XPEL assists wastewater plants receiving food-processing effluent by reducing the overall hydraulic load created during washdown, cooking and cleaning operations.

-

Oil and gas plants treating produced water and process-affected streams gain additional buffer capacity when XPEL lowers incoming volume before it reaches primary treatment stages.

-

Where mining runoff or process water enters wastewater facilities, XPEL reduces the inflow burden so plants can maintain more consistent system behaviour.

-

Municipal wastewater plants facing variable domestic and industrial inflows use XPEL to manage excess water during seasonal peaks or wet-weather events.

-

Legacy and industrial sites treating accumulated or contaminated water from older facilities benefit when XPEL decreases volume inflow, allowing treatment assets to function within their design limits.

-

Pulp and paper mills often generate high-load influent. XPEL reduces the volume entering treatment systems so equipment can operate more predictably.

-

Manufacturing facilities operating under variable flow conditions achieve operational stability when XPEL pre-emptively reduces water volumes during production cycles.

PRODUCTS

Land based

evaporators

Fully customisable and bespoke in design, our XPEL land based water evaporators are available in a range of sizes enabling operators to reduce the risks associated with excess water and ensure environmental compliance with a wide range of water processing capabilities.

Pontoon

evaporators

When land based units aren’t an option, the XPEL Pontoon Series evaporator is a water management solution that can be relied on to help reduce the risk of excess water and ensure environmental compliance by reducing the volume of water stored on-site using mechanically enhanced evaporation.