Industrial water evaporation technology.

XPEL™ powered by Minetek.

XPEL water management solutions backed by more than 35 years of engineered evaporation technology, helping critical industries manage water sustainably at scale.

OUR CAPABILITIES

XPEL water evaporation systems offer the world’s most extensive and cost-effective approach to large-scale wastewater reduction.

Each system is engineered to cut risk, control excess water and support long-term environmental compliance across diverse industrial and municipal conditions.

XPEL water evaporators help operators meet and exceed their water management objectives through efficient, sustainable and commercially grounded evaporation performance. The technology is purpose-built to remove large water volumes while lowering operating costs and enabling teams to maintain safe, reliable production.

With over 700 projects delivered across more than 30 countries, XPEL solutions operate in some of the most demanding environments worldwide. We draw on decades of proven engineering and field experience to deliver mobile, flexible and high-performance systems trusted across critical industries.

Water management industry applications

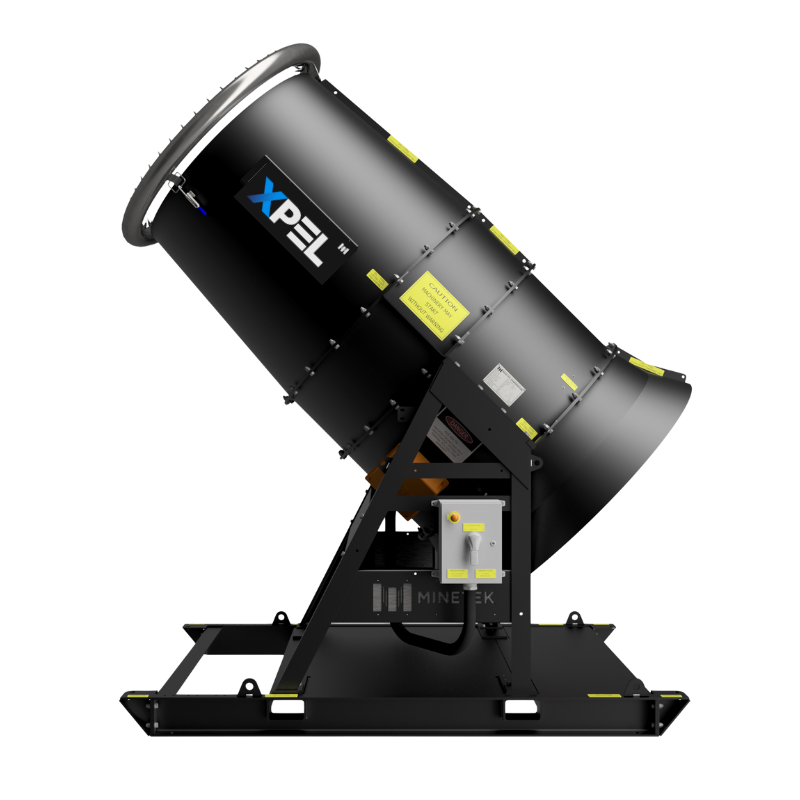

Meet the XPEL water evaporator

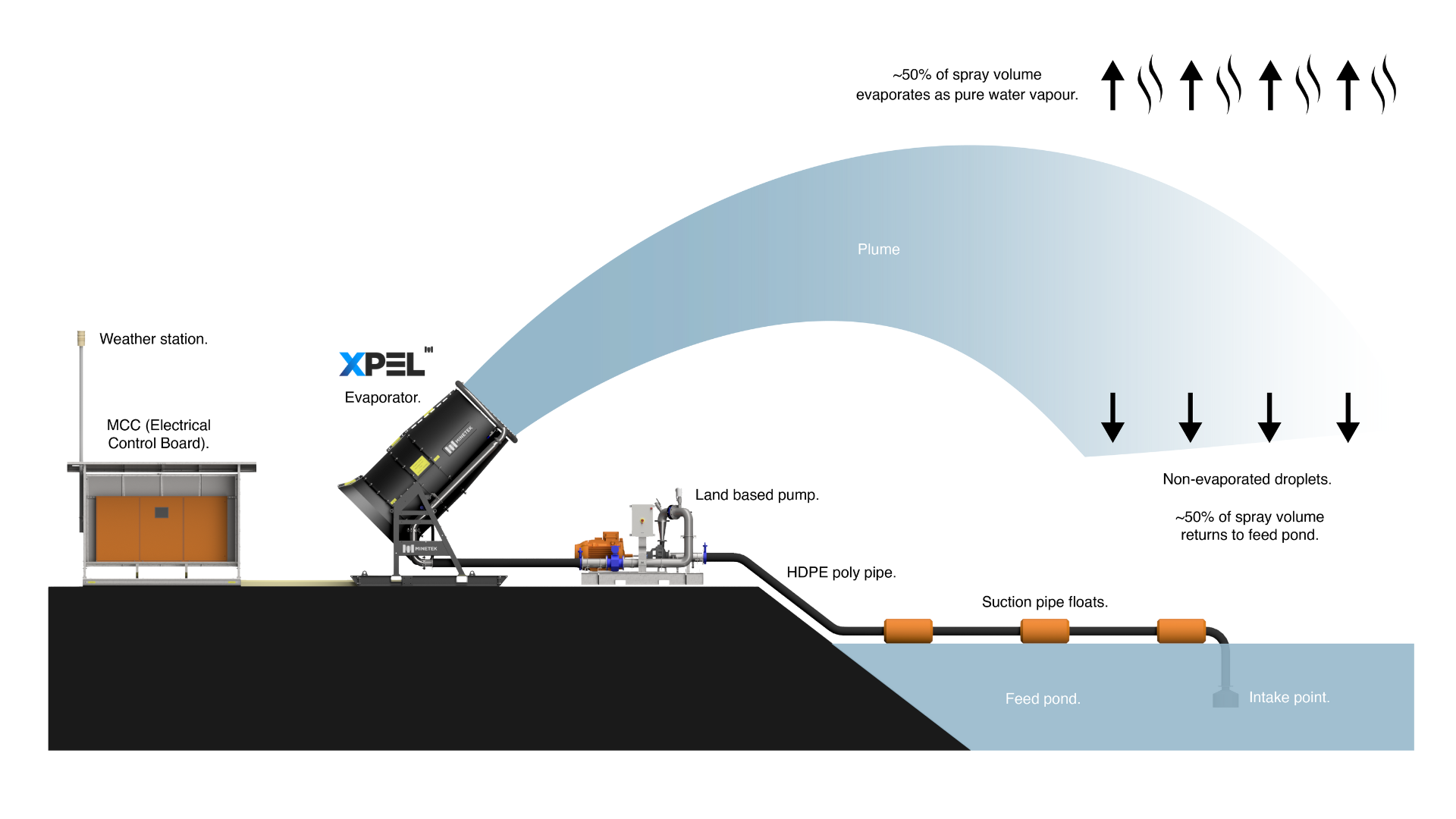

Unmatched performance

Fully engineered for variable industrial conditions with customizable configurations, advanced water-handling capability and proven performance across diverse climates. Each system can be modeled through site-specific evaporation analysis to predict efficiency in the operating environment. Integrated Environmental Management System (EMS) track humidity, rainfall and wind in real time to optimize evaporation rates, support compliance, and maintain consistent, reliable performance.

“Good product with great service leads to a great outcome.

My dealings with XPEL and their supply and service of evaporators were one of high quality. I installed 10 evaporators on climate control to maximize efficiency and the results were incredible. From the first meeting through to commissioning nothing was a problem for the XPEL team.

I would highly recommend this product to anyone with water disposal issues.”

- Coal mining site operations manager

Proven water

evaporation technology

Built for demanding industrial and municipal settings, offering high-volume output and stable operation across varied climates and water qualities. XPEL water evaporation units support critical industries with steady, high-capacity evaporation suited to large-scale operational demands.

30+ countries.

600+ projects.

Proven performance.

Leading industrial water management solutions

XPEL is a global industrial solutions provider with decades of experience supporting a broad range of industries, including food processing, oil and gas, mining, government and municipal operations, pulp and paper, and manufacturing and legacy industrial sectors.

Backed by more than 700 projects across 30 countries, XPEL water powered by Minetek draws on deep engineering, design and field experience. This capability ensures that every solution is built to rigorous technical standards and performs reliably across diverse climates and water quality conditions.

XPEL water systems deliver steady, high-volume evaporation suited to complex industrial and municipal conditions. Each unit is designed to process variable water quality while supporting safe, compliant, and predictable operations in complex industrial and municipal environments.

These solutions reduce stored water volumes, strengthen environmental responsibility and improve long-term site resilience. XPEL helps critical industries align with regulatory expectations while supporting reliable, profitable operations.

Low Fouling Nozzles

Engineered to process acidic, caustic, high-TDS and high-TSS water across the full pH range while maintaining consistent evaporation output.

Construction Materials

Built with site-matched material options designed to withstand harsh chemistries and demanding industrial environments.

Water Rail

Supplies high-volume wastewater to the nozzle array for controlled atomization and efficient evaporation performance.

Rapid Deployment

Integrated lift points and forklift pockets enable fast relocation across ponds, dams or site layouts.

Compact & efficient

A small footprint, low power demand and minimal moving parts drive strong operational efficiency and long-term cost control.

View our latest

success story

We collaborated with a food processing facility in Missouri, USA to address critical water management needs for their onsite holding pond. The solution involved a turn-key land-based evaporation system supported by integrated environmental management controls.

Featured case studies

Water management FAQs

For a deeper understanding of how XPEL’s water evaporation systems can transform your operations, we offer a comprehensive list of Frequently Asked Questions.

This resource covers everything from technical specifications and customisation options to regulatory considerations and environmental benefits.

Explore the full FAQ section and discover how our solutions can be tailored to your unique requirements.

-

XPEL's Evaporator technology stands out for its ability to treat a wide spectrum of water types. Deployments worldwide demonstrate success with waters spanning different pH ranges, acidic or alkaline profiles, elevated Total Dissolved Solids (TDS), and substantial Total Suspended Solids (TSS).

-

The specialized nozzles in XPEL Evaporators are engineered to accommodate particles of various sizes, which plays a key role in extending equipment life, enhancing resilience, and maintaining peak operational efficiency.

-

In cases of highly concentrated brines with extreme TDS, occasional freshwater rinses might be necessary to avoid clogs. These can be performed either by hand or through automated sequences. Additionally, XPEL™ can integrate a complete stainless steel filtration setup at the intake to block solids from reaching the core evaporation components.

-

XPEL's evaporators are proven in global installations across extreme settings, from humid tropical zones and seasonal cold snaps with snowmelt to dry desert regions.

-

XPEL™ tailors its equipment to accommodate virtually any water challenge, using an array of construction materials to guarantee durability and suitability for the toughest scenarios.

-

Through XPEL's Environmental Management System (EMS), operations pause or resume based on user-defined criteria like precipitation, ambient temperature, wind velocity, and direction to minimize unintended dispersal.

-

Accessible via remote desktop, the weather module tracks factors such as relative humidity, precipitation, gust speeds, potential drift distance, prevailing winds, and customizable runtime schedules.

-

This approach generally lacks prior regulatory benchmarks since it amplifies a natural evaporation process via mechanical fans. XPEL™ stands ready to guide clients through any necessary approvals.

-

Absolutely. Customizations encompass power specifications, build materials like galvanized steel, stainless variants, or advanced epoxy finishes, adjustable spray orientations (vertical and horizontal), safety access platforms with barriers (for stationary models), noise attenuation kits, and fully automated climate controls.

-

Indeed, XPEL™ delivers comprehensive project handling for those seeking a seamless experience, covering initial evaluations, full design and fabrication, right through to powered-up, automated deployment. This extends to on-site activation and staff training.

-

By evaporating water on-site, XPEL™ eliminates discharge needs, safeguarding nearby waterways, wetlands, and habitats. Treating issues at the origin prevents broader ecosystem harm and pollution risks.

Without a reliable water management solution, the facility faced challenges in maintaining safe water levels and adhering to stringent environmental standards, which could impact both productivity and regulatory compliance.